Powder Coating Troubleshooting Guide

Chapter Seven: Powder Application Methods and Equipment

The method chosen to apply powder coatings is varied depending upon the specific part. Fortunately powder coating technology offers many choices in the application process.

|

Factors to Consider in Coating Methods

|

Application Methods Available

|

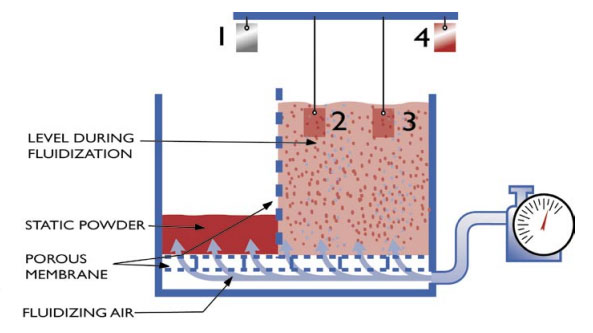

The fluidized bed process is used for coatings between 10-15 mils with the final thickness dependent upon part temperature and dip time in the powder. The film can be applied in thickness from 8-125 mils. This process requires pre-heat temperatures of at least 350°F and may require a post-heat or cure cycle.

Typical Uses:

Buss bars, transformers, fabricated wire, metal furniture, raceways

Steps:

- Part pre-heated to 400°-450° F

- Initial deposit melts onto part

- Film builds from residual heat

- Coated part with desired film

Advantages:

- Uniform coating

- Product reliability

- Thick coatings

- Complex parts 100% coverage

- Good edge coverage

- Good process control

Disadvantages:

- Pre-heat and post-heat ovens required

- Larger heavy parts must be manipulated into bed

- Thinner substrates do not hold heat, difficult to coat

- Complex shapes trap excess powder

- Minimum of 8 mils to be applied

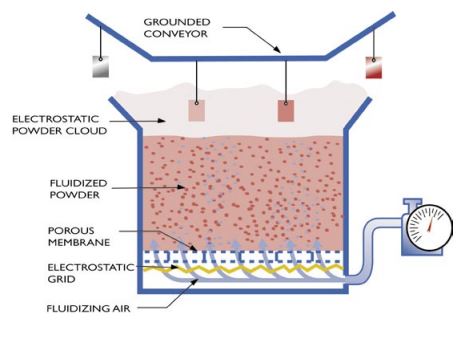

Electrostatic fluidized beds are especially applicable to continuous coating of sheet, wire screen and small simple configuration parts. The effective coating range is only 3-4 inches over the bed and will not coat parts with deep recesses. Coatings range from 0.8 to 3 mils on relatively high speed lines.

Advantages:

- High speed lines

- Easily automated

- Thin films possible

- Acceptable to continuous length products

Disadvantages:

- Coating area limited to 3-4 inches above bed

- Restricted product flexibility

- Best for 2 dimensional parts

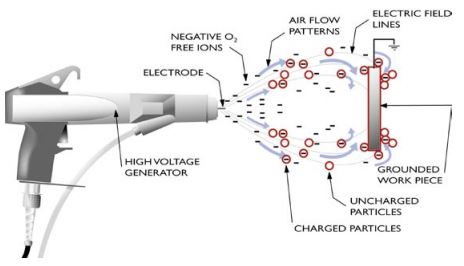

Corona charging is the most common application method used in powder. The process disperses finely ground powder into an airstream, producing a cloud as it exits the gun. The particles pass through a highly charged and ionized corona field at the gun tip, applying a strong negative charge to each particle. These particles have a strong attraction to the grounded part and deposit there. This process can apply coatings between 0.8 and 10 mils in thickness. Corona charging can be used for decorative as well as functional coatings. Virtually all resins with the exception of nylon can be applied easily with this process. Making color changes in this type of system varies. Most handgun operators can change over box units in less than 10 minutes. Hopper changes can be as little as 20 minutes if using the same hopper. Color change times for standard systems average between 45-60 minutes

Advantages:

- Heavy films

- High transfer efficiency

- Only one oven, spray parts cold

- Applies quickly

- Can be automated

- Minimum operator training

- Works with most chemistries

Disadvantages:

- Difficult color changes in automatic systems comparable to Tribo systems

- Requires high voltage source

- Some difficulty with deep recesses

- Thickness control sometimes difficult

- Capital cost higher than other application methods

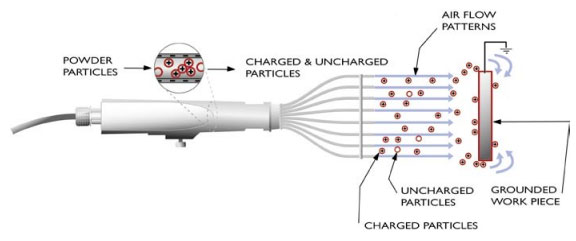

Tribomatic static charging is the second most common method of spraying a powder coating. This method relies on the powder to develop a charge while passing through special hoses and guns. As powder contacts these non-conductive surfaces, electrons are stripped off of the particles due to friction. These particles then develop a powerful positive charge. No high voltage or lines of force are used which allows for easier penetration into deep recesses. Tribomatic charging is efficient in developing a static charge within the powder, however, coatings must be specifically formulated for this system.

Advantages:

- No high voltage source required

- Better penetration into recessed areas

- Slightly lower capital costs

Disadvantages:

- Level of charge varies with powder chemistry and formula

- Slower rate of application

- Transfer efficiency is lower than corona charging system

- Requires more guns

- Wears out parts faster

| Critical Variables | Corona | Tribomatic | ||

| Faraday Cage | More difficult to coat recesses | Easier to apply to recesses | ||

| Back Ionization | Easier to coat thinner films | Easier to produce thicker films | ||

| Product Configuration | Not good for complex shapes | Very good for complex shapes | ||

| Production Requirements | Wide range of line speeds | Good for lower line speeds | ||

| Powder Chemistry | Less dependent on chemistry | More dependent on chemistry |

Contact us today to speak with our experienced team about how we can help you with your powder coating needs.

Other Chapters

- Early Powder Coatings, Uses, and Types

- Manufacturing of Powder Coatings

- Powder Chemistries, Formulations, Comparisons, and Uses

- Comparisons to Liquid Coatings

- Measuring Up the Product

- Pretreatment

- Powder Coating Recovery Equipment

- The Electrostatic Charge Process

- Powder Application Tips

- Powder Curing Process

- Safety Issues With Powder Coatings

- TCI Troubleshooting Guide

- Glossary of Industry Related Terms